The Single Strategy To Use For Bulk Materials Handling

Wiki Article

What Does Bulk Materials Handling Mean?

Table of ContentsAll About Bulk Materials HandlingSome Known Details About Bulk Materials Handling The 6-Minute Rule for Bulk Materials HandlingThe smart Trick of Bulk Materials Handling That Nobody is DiscussingBulk Materials Handling - An Overview

People have traditionally produced products making use of raw products. This form of manufacturing is often connected with decorative art, fabric production, leatherwork, woodworking, and also some metalwork.As an example, one-of-a-kind handcrafted fashion products can be offered at a higher cost compared to something mass-produced. There are instances, however, where individuals who make goods utilizing these strategies can be exploited, particularly where labor laws are lax as well as demand for jobs is high. Bigger companies make use of automation to mass-produce products on a much grander scale.

Ford promoted mass-production methods in the early 20th century. Computer systems and also accuracy electronic tools have given that allowed firms to leader high-tech manufacturing methods.

The abilities needed to operate equipments and also develop manufacturing procedures have actually drastically changed over time. Several low-skill manufacturing tasks have shifted from established to establishing nations due to the fact that labor in creating nations has a tendency to be cheaper. Because of this, premium items that need precision and proficient production are usually created in established economic climates.

The Best Guide To Bulk Materials Handling

Although the volume and also number of products made have actually boosted, the number of employees required has actually declined. Measuring Manufacturing in the Economic Climate Economists and federal government statisticians use various ratios when examining the function production plays in the economic situation. As an example, producing worth included (MVA) is an indication that contrasts an economic situation's production output to its overall dimension.

The development of 3D printing is making it simpler for people to generate finished goods themselves, without ever before leaving their very own residences.

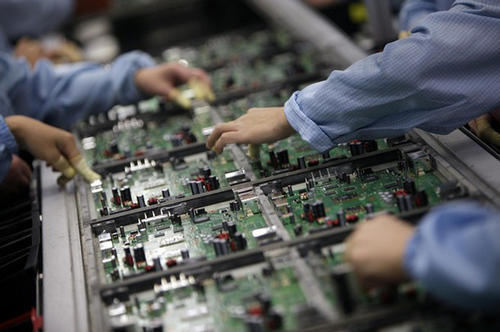

Manufacturing, The starting point we visit is the manufacturing center of the business. The manufacturing facility is the center where the organization builds its products. Another name for this kind of center is an industrial center. The company has both hefty production centers as well as light commercial facilities. It is in the hefty manufacturing facilities that the business makes every one of their huge and very cumbersome products, such as their large-screen tvs.

An Unbiased View of Bulk Materials Handling

Considering their centers, it's amazing how smoothly every little thing is working. The firm agent informs us that making their very own items and maintaining their procedures smooth are a pair methods they keep rates reduced and also quality high. Not all organizations resemble Make-All Sell-All, though, and the interpretation of heavy as well as light manufacturing can differ depending on the firm.In other words, what certifies as a hefty manufacturing center in one service could certify as a light manufacturing center when compared to various other businesses. Retail, The next location we check out is among Make-All Sell-All's retail locations. The retail facility is the center that sells items to the public.

Below is additionally where consumers purchase these items. The business rep states that running their own retail facilities likewise assists maintain prices reduced. If you stroll around any kind of buying facility, you will certainly see several retail stores. A few of these company website are marketing their own products. Others offer products from several manufacturers along with their own visite site items, if they make them.

Some Of Bulk Materials Handling

The business agent informs us that maintaining their own solution centers likewise maintains prices low (bulk materials handling). It is excellent to bear in mind that there are companies that just supply service; therefore, they just have service facilities. A carpeting shampooing business just requires a service center that sends out the rug shampooing vans to its consumers.In fact, a lot of organizations need every one of these centers to operate. If business does not have a details center, then they need to work with one more company that does have that center. For instance, if a tennis shoe company doesn't have a fixing center, then they will certainly require to function with another business that has a center that does athletic shoe repair.

The manufacturing facility is the center where the service develops its products. The solution facility is the facility where repair services and also other solutions are used.

Understanding Outcome, As quickly as you've studied completely, see if you can create a list of the various facilities click for more info a company requires to create, sell, and also repair its items, and also discuss what happens in each center. To unlock this lesson you have to be a Member. bulk materials handling.

See This Report on Bulk Materials Handling

Report this wiki page